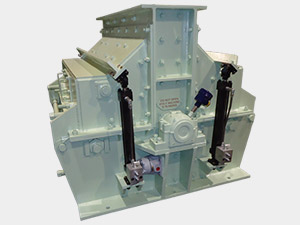

American Pulverizer Impactors all operate on the same principle. The infeed material enters the impactor through the feed chute and is engaged by the rigid rotor hammers and hurled against the impact arms. Reduction is caused by impact against impact curtains and rigid hammers and by collision with new infeed material entering the crusher. This true impact principle promotes a uniform cubical product.

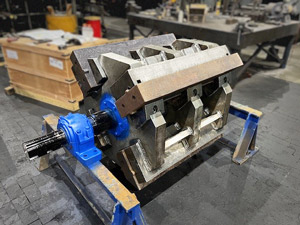

Impactor rotors revolve vibration-free in a rib-reinforced housing. The rotor is provided with replaceable hammers, cast from manganese steel or a hi-chrome alloy. These hammers project the feed material against the two impact arms in the crusher housing to continue to the crushing process. The impact curtains direct the feed material back into the hammer tips. Reduction continues until the feed material is fine enough to pass through the gaps between the impact arms and the hammer top circle.

Product size can be controlled by externally raising or lowering the arms. The rotor speed also greatly influences sizing.

Types of impactors include:

Contact Us For questions or other information about American Pulverizer Impactors.