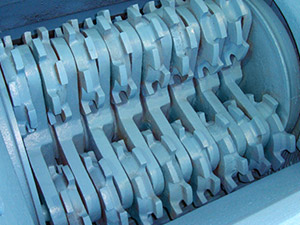

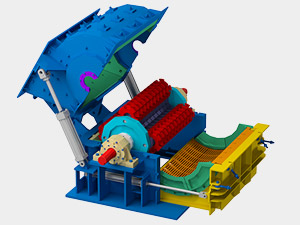

American Pulverizer Ringmills utilize an exclusive rolling ring design that is the most efficient crushing element ever developed to reduce material to uniform size. Each ring freely rotates on the shaft and is held in its outward position by centrifugal force. This process reduces by impact rather than sharpness and is free to deflect from tramp metal. Rings are reversible for double wear.

Shredder rings are used when a minimum of fines is desired, smooth rings when a maximum of fines is required.

The rotor's heat-treated steel main shaft revolves in heavy-duty anti-friction bearings, which are enclosed in dust- and air-tight pillow blocks. Rings are installed in a staggered formation covering the entire width of the crushing chamber.

Contact Us For questions or other information about our ringmills.